ABSTRACT

A laser-based contact less displacement

measurement system is used for data acquisition to analyze the mechanical

vibrations exhibited by vibrating structures and machines. The analysis of

these vibrations requires a number of signal processing operations which include

the determination of the system conditions through a classification of various

observed vibration signatures and the detection of changes in the vibration

signature in order to identify possible trends. This information is also

combined with the physical characteristics and contextual data (operating mode,

etc.) of the system under surveillance to allow the evaluation of certain

characteristics like fatigue, abnormal stress, life span, etc., resulting in a

high level classification of mechanical behaviors and structural faults

according to the type of application.

Smart sensors or latest

generation sensors are now use for vibration measurements. Where the first

generation sensors are piezoelectric

accelerometers, second generation sensors are modification of piezoelectric accelerometers and

latest are the smart sensors. Third-generation smart sensors use mixed mode

analogue and digital operations to perform simple unidirectional communication

with the condition monitoring equipment.

INTRODUCTION

The study of vibrations

generated by mechanical structures and electrical machines are very important. The

advent of machines and processes that are more and more complex and the ever

increasing exploitation and production costs have favored the emergence of

several application fields requiring vibration analysis. Among these application

fields, we find machine monitoring, modal analysis, quality control, and

environment tests. These functions are used in fields such as aeronautics,

space industry, automotive industry, energy production, civil engineering, and

audio equipment.

The signal processing

application described here uses a laser-based vibrometer in order to analyze

the vibrations exhibited by mechanical systems. This technique can be used in

the numerous applications mentioned above. The problem is to develop an

intelligent system that has the ability to determine the system conditions

based on a classification of the possible vibration signatures, detect changes

in the vibration signature, and analyze their trends.

The classification of the

various possible vibration signatures requires a priori knowledge of the

mechanical system under healthy conditions as well as for the various fault

conditions; when possible a mathematical model of the system should be

provided. The latter is often crucial for the good interpretation of the

observations, since it predicts the dynamic behavior of the structure and thus

the healthy vibration signature.

Vibration spectra are in

general “peaky” due to either the periodic nature of the system’s excitation or

to the natural resonance properties of the mechanical system. Changes in a vibration

signal can result from a variation of the amplitude, frequency, and/or phase of

one or many of the components. Moreover, new peaks may add to the existing

spectrum, or some peaks may fade out. Changes can also appear in the form of

short transients or spikes in the time domain. At the extreme, if the

vibrations become so strong that the structure actually starts to move, then

the overall average level of vibration would change, that is, a DC component

would appear.

All of the above changes may

occur gradually, like fatigue stress slowly deteriorating the material’s

properties, or they may occur suddenly, like the rupture of a mechanical part within

a machine. They may also occur periodically or in a random fashion depending on

the process generating the vibrations. For multiple state systems, changes must

be interpreted carefully. For example, if the operating speed of a rotating machine

is raised from A to B, the vibration analysis system should not declare the

observed changes as being the result of a mechanical failure, but should adapt

itself to this new mode of operation.

LASER VIBROMETER

The laser vibrometer is a

transducer which converts relative displacement into an electrical signal

readily available for digital signal processing (DSP). Laser-based systems

provide several advantages over conventional accelerometers since the

measurements are performed in a contact less manner, i.e., the transducer does

not affect the dynamic behavior of the system under measurement. This is

especially important in the case of light-weight and low-density structures.

Vibrations can be measured remotely and in environments presenting hostile

Conditions such as high

temperature, pressure, and electromagnetic fields the frequency range of the

laser vibrometer extends down to DC which is not possible with most

accelerometers. There is no calibration required since the basic unit of

measurement is the laser wavelength λ.

A schematic of the laser

vibrometer is shown in Fig. 1. The optical portion of the vibrometer is a

Mach-Zender interferometer. The laser beam is split into a reference beam and a

measurement beam which is directed toward the moving target; this beam is then

reflected back into the interferometer. Polarizations, as shown by arrows and

dots, are used in order to combine the beams properly. The recombination of the

beams results in interference since the moving target changes the length of the

measurement path while the length of the reference path remains constant. The

resulting light intensity recorded at the detector is maximum when the phase difference

between the beams equals an integral multiple 2π of, i.e., an integer number of

wavelengths λ.furthermore, to

provide the direction of motion of the target; the reference beam is single

sideband phase-modulated with an acousto-optic modulator.

The

actual displacement measurement is performed by counting the number of maximum

intensities (or fringes) encountered as the moving target constantly shifts the

phase of the measurement beam. In other words, a count of one means that a

displacement of (i.e., a phase shift of 2π) has been recorded. Note that a change

of λ in the total measurement

path length (incident plus reflected) corresponds to an actual target

displacement of λ/2

The digital displacement signal

is provided by an electronic module (not shown in Fig. 1). The electronic

module filters and demodulates the detector signal into an in-phase (I) component

and a quadrature (Q) component. Both I and Q signal components are then

converted to logic levels and are fed into a quadrature decoder. By decoding

all of the possible I-Q transitions, the displacement resolution is effectively

increased by a factor of four. The decoder outputs, which consist of a counter

trigger and a direction flag, drive a counter, the output of which represents

the target displacement. Because of the quadrature decoder, a count of ± 1

indicates a displacement of ± λ/8;

this means that for a HeNe laser with λ=632, 8 nm,the maximum resolution is

equal to 79,1nm.

VIBRATION ANALYSIS PROCESS

The first step in the vibration

analysis process is to identify a set of parameters which can be used for

vibration analysis. These parameters reflect the physical characteristics of

the system, and each parameter represents a particular feature of the vibration

signature. The parameters may be determined theoretically from a mathematical

model, intuitively by inspection or simple deduction, or experimentally. Fig. 2

shows the vibration analysis system used

.

The second step is to create a

classification space based on the parameter set. The classification space

contains a healthy area or sub-space corresponding to the normal dynamic behavior,

and one or more fault areas corresponding to the various possible fault cases

[1]. Areas are obtained through training either from a set of actual

experimental data or from simulations. Each area then forms a cluster in the classification

space.

The signal processing

requirements for vibration analysis must fulfill three goals. First, the raw

signal must be conditioned and transformed in order to map the vibration signature

to the system parameters. Second, decision tools must be able to evaluate the

system conditions by classifying the observed parameters according to the

discrimination rules. The discrimination rules for choosing which

classification area a given observation belongs to is based on an existing pattern

recognition technique. Popular techniques include nearest-neighbor, neural

networks, template matching, statistical methods, etc. Third, adequate tools

must be able to detect changes in the parameters. The observed trends must be analyzed

in order to eventually predict the future behavior of the system.

Changes in a vibration signal

due to failures are intrinsically non-stationary phenomena. The use of

stationary analysis techniques can sometimes be justified in situations where

the observed changes are slowly varying, thus providing a piecewise stationary

signal. However, this is not always the case for mechanical failures. Changes

are therefore best analyzed using non-stationary transformation techniques. Unlike

stationary techniques, they allow the detection of incipient failures which, at

their early stage, often occur in a non-repetitive manner in the form of

transients . In this case, non-stationary techniques should be used for the

signalto- parameter transformation task.

Data acquisition can be

performed in two different modes: continuous mode and sample mode. The

continuous mode performs a non-stop surveillance of the mechanical system. In this

mode, data is acquired and processed continuously in real time. In the sample

mode, finite length data are collected and the processing can be performed

either in real time or off-line. The choice of one particular mode over another

is a function of the application. Note that trend analysis can be performed in

either mode and can cover multiple time scales.

APPLICATION: GEAR SYSTEM

The vibration analysis system

was used for the detection of broken teeth in gears. The type of defect that we

want to study is the presence of a broken tooth on one of the gears. The passage

of the broken tooth on the engagement point creates a discontinuity in the load

applied on the gears, resulting in the generation of a pulse once every

rotation . The signal can therefore be mathematically described as follows:

Where τe is the period

of engagement, he is the signal generated by the contact of the teeth at

the engagement point and is defined on the interval [0, te]. The

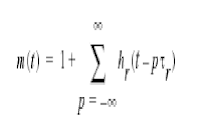

modulation term, m(t), is defined as:

Where τr is the period

of rotation of the defective gear and hr is the pulse signal due to the

broken tooth and is defined on the interval [0, tr].

More precisely, the mechanical system

consisted in two gears, one with 15 teeth (gear 1) and the other with 36 teeth (gear

2). Three cases were analyzed. Case A was when both gears presented no

imperfections. In case B, gear 1 had a broken tooth and gear 2 was normal,

while in case C, gear 2 that had a broken tooth and gear 1 was normal.

In order to characterize the

imperfections, we have used the auto covariance of the spectrum of the

vibration signature, given by:

where X is the vibration

signature vector of length N, n is the frequency index, and d is

the frequency displacement index. The spectral auto covariance measures the

degree of correlation of the spectrum with itself. If the spectrum has e q u i

d i s t a n t f r e q u e n c y c o m p o n e n t s , t h e s p e c t r a l auto

covariance will contain peaks at the frequency displacements corresponding to

multiples of these frequency components.

Fig. 3 shows the operations

performed. We have focused our attention on the maxima at 19.5 and 46.9 Hz, the

frequencies corresponding to the rotating speed of the broken gears. We performed several measurements. The

results were put on a two dimensional classification space. The classification

regions for the three cases are clearly identifiable. These regions are

obtained using the technique of principal components. In this method, each

region is delimited

by an ellipse, oriented according to the

eigenvectors of the covariance matrix of the observations .

We should mention that is not at all excluded

that another defect (a different broken tooth) could be classified in one of the

three classes. Since we are only using the presence of multiples of 19.5 Hz and

46.9 Hz frequency components in the spectrum, other phenomenon causing these

frequencies could be detected and fall within one of the three classes. Misalignment

and eccentricity of the gears are two examples of situations that can generate

spectral components at harmonics of the rotating frequency. Also, since we are limited

to three classes, a defect not considered in our model (e.g. two broken teeth)

could not be detected. We thus have to be prudent in the use of this apparatus

and in the physical interpretation of its results.

Another important factor is the

rotation speed. In our experiments, the gear system was rotating at a constant

speed, resulting in spectral components at constant positions. The parameters

of the system were thus oscillating around an average value. An increase or a

decrease in speed, as would be the case in the gear box of a truck, would

produce erroneous results, because our system was calibrated for a certain

speed.

NEXT GENERATION SENSORS

Piezoelectric

accelerometers are the most common vibration sensor technology used in

condition monitoring systems. These sensors have evolved from the first

generation; un amplified ‘charge mode’ sensors used during the 1960s to the

second-generation, internally-amplified designs that are widely used today.

Second generation transducers convert the low-level or high-impedance charge

output of a piezoelectric crystal into a low impedance, voltage output signal

by using internal amplifier circuitry. Through advanced amplifier design,

second generation transducers can provide protection against over-current,

reverse powering, radio frequency (RF) interference, shock, electrostatic

discharge (ESD), and inter-modulation distortion. Smart sensors The

introduction of ‘smart sensors’ began with third-generation vibration

transducers. Third-generation smart sensors use mixed mode analogue and digital

operations to perform simple unidirectional communication with the condition

monitoring equipment. After the proper triggering protocol has been received,

the smart sensor outputs all of the digital information stored in its digital

electronic ‘data-sheet’. Once the data transmission from memory is complete,

the sensor immediately returns to a second generation mode of operation where

it continues to output an analogue signal that is proportional to the vibration

input. The two-wire interface makes the sensors compatible with the existing

legacy systems.

Third-generation, smart mixed-mode

accelerometers are already used in embedded military applications. Using a

current detecting operational amplifier, the digital electronics are triggered

by a 2 mA drop in the current source that lasts for 11 ms. Programmable read

only memory (PROM) chips store an auto-test sequence and a sensor

identification code that consists of manufacturer, model and serial number

codes. Figure 2 shows the digital output sequence for the sensor used in this

application.

FOURTH GENERATION SENSORS

The development of

fourth-generation smart vibration sensors has not happened as quickly as many

had envisaged. The development of smart sensors for condition monitoring

applications has lagged behind the development of smart pressure, temperature,

flow and other sensory modalities primarily because of the shear magnitude of

data to be processed and transmitted. Fourth-generation smart vibration

transducers will be characterized by a number of attributes. These are:

1.

bi-directional command and data communication;

2.

all digital transmission;

3.

local digital processing;

4.

pre-programmed decision algorithms;

5.

user-defined algorithms;

6.

internal self-verification or self-diagnosis;

7.

compensation algorithms; and

8.

On board data/command storage.

Figure 5 shows a block diagram

of a fourth-generation smart vibration transducer.

Bi-directional Communications

In contrast to third-generation

smart sensors, which have unidirectional control and data communication, the

functions built in to fourth-generation smart sensor allow them to send control

commands to the decision support processor and accept commands. Data flow will

be bi-directional, which means that the user can download information to the

sensor, and upload it from the sensor. For this reason a particular mounting

point can maintain location- specific data — even when the sensor is replaced —

by downloading the old sensor’s site-specific data before it is replaced.

All-digital communications

Another feature of a

fourth-generation smart sensor is that all communications are performed

digitally. One particular benefit is error immune transmission that results

from the use of techniques such as parity, cyclical redundancy checks (CRCs),

or check sums followed by a re-transmission of missing or corrupted data.

Electromagnetic interference (EMI) concerns are therefore greatly reduced.

Cable runs using regeneration techniques such as repeaters will enable data to

be transmitted over extremely long distances without it being corrupted.

Fourth-generation smart vibration transducer networks are expected to use

two-wire interfaces and a daisy-chain topology. This structure minimizes

cabling cost per unit length, and it simultaneously minimizes total cable usage

(length) in a given application. Two-wire networks have been identified by a

number of user-groups as the desired solution for sensor networks.

Local digital processing

Recently significant processing

power has become available at a low cost. This combined with low-cost

sigma-delta analogue-to-digital (A/D) converters will be responsible for

revolutionary changes in monitoring technology. Does this mean that centralised

conditionbased monitoring (CBM) processors will disappear, and all processing

will be performed by the smart sensor? The answer is unequivocally, no. The

processing power of distributed sensors will actually enhance CBM capabilities.

With hundreds of individual smart sensor DSPs each calculating their own Fast

Fourier Transform (FFT) functions, higher order FFTs could be calculated in the

same time that current systems take to calculate one FFT. This would lead to

more powerful and sophisticated algorithms involving phase and complete vibration

state analysis of machinery vibration. Subtle changes in machine state that

currently go unnoticed will be recognised as significant indicators of

machinery health. This higher order analysis can only be performed by a central

processor that integrates all of the sensor states into a single cohesive unit.

Combine this with temperature data from each sensor and the number of

possibilities is enormous. ‘Sensor fusion’ can only occur at the higher

processor level which takes into account the overall picture of machinery

condition and health. Think of this as a ‘whole-body gestalt’ of condition

monitoring. This is akin to a mechanic that analyses a problem by integrating

knowledge, feel, observation, temperature and sounds.

Pre-programming

The algorithms that can be

embedded in a smart transducer range from ones which are simplistic in nature

to those which are highly sophisticated. Alarm-level triggering, based on

absolute levels is an example of simple decision making. More sophisticated

types of alarm-level triggering are priority levels, delta change, windowing

and band alarming. Even more sophisticated concepts such as neural nets and

fuzzy logic could be used within the sensor to aid in localized decision

making. Historical data comparisons such as trending of data also could be

easily performed by an intelligent sensor. Interestingly, the storage

requirements for trending are minimal, since spectral data is a very compact

representation of considerable real-time data.

Defined by users

This level of functionality

would allow each sensor’s computational power to be tailored to the specific

needs of the customer. For example, after an accelerometer has been in place

for a few months, the user may decide that its amplitude range is too low

during machine start-up and shut-down, resulting in distortion, but perfect for

normal operation. The sensor could be commanded to lower the gain during

start-up and shut-down, and then increase the gain as a function of machine

stability and speed, for maximum resolution during normal operation. The

concept of extensible sensor object models would allow local smart sensors to

be reconfigured for new tasks when required.

Self-verification

Sensor data will also become

more reliable in fourth-generation sensors, because such devices will be able

to constantly monitor their own health. These capabilities can be built into

both software and hardware to ensure sensor integrity. Instances can occur

where CBM systems are unaware that a sensor has failed because a faulty sensor

is mimicking a healthy machine. In addition to self-verification, another

useful smart sensor function would be a self-diagnostic capability. Once an

error has been detected, the ability to diagnose the problem and localized the

fault will ensure that the problem is fixed quickly. Also, when a problem is

suspected by the user, the capacity to command all sensors to verify and

diagnose can help to locate hidden problems.

Compensation algorithms

A smart sensor can monitor

parameters such as temperature, age and signal amplitude, and compensate

directly for local conditions. For example, piezoelectric crystal sensitivity

changes with age. Smart sensors could automatically compensate for this drift,

saving any costs that are associated with re-calibration. Another compensation

algorithm — direct compensation of sensor non- linearity, that is, calibration

— could be implemented by using look-up tables to linearize the output to a

high degree of accuracy. In Figure 6 a sensor which is attached to a machine

with a ‘glitch’ can be easily compensated in the frequency domain by applying a

simple algorithm.

All instrumentation systems are

affected by temperature, but these effects can be readily removed by a smart

sensor before the data is even processed. Yet another compensation technique

involves rescaling of the input amplitude to the amplifier to prevent ‘wash

over’ distortion from ‘aliasing’ the data.

On board storage

A main advantage of a sensor

having on board storage is that it allows look-up tables to be used to adjust

and/or compensate for sensor environmental deviations. For example, if once

every fifteen seconds a large transient occurs, brought about by another

machine’s operation, the sensor can create a look-up table that compensates for

the transient deviation, thereby avoiding false triggers. There are other

important advantages of having on board storage. In general, most CBM systems

are typically set by the users to ‘round-robin’ poll the sensors once a day,

with once-an-hour polling being the exception rather than the rule. This means

that if random or unexpected events occur, the likelihood of catching an event

is small. Dedicated sensor processors would allow the CBM manager to record all

significant events for subsequent analysis. This form of event storage would be

similar to an aircraft’s ‘black box’. This could be easily interrogated after

an unexpected accident. Another feature of on board data and command storage is

that it enables extensible object models to be downloaded and uploaded. The

means that the sensor can be represented as an ‘object’ to the CBM system — an

‘object’ that has all of the associated benefits of object-oriented programming

such as reuse and portability, type casting, information hiding, specification

and re-specification of allowed operations and domain values, and machine or

application independencies.

Sensor reality

The realization and

implementation of fourth-generation CBM sensors ultimately will be decided by

the market-place. Customers will base their decisions on cost, size, interface

utility, functionality, and most importantly the benefits that they can

potentially gain As processing and decision support are incorporated into the

sensor package — at low-cost through the use of ASICs — and if the data can be

accessed in real-time without simplification, fourth-generation CBM smart

sensors will become a reality.

CONCLUSION

We have used the vibration

analysis system for the detection and the characterized of broken teeth in

gears. Our results show that the laser-based measurement system can detect gear

imperfections and successfully classify them. The system is both highly

sensitive and very accurate. Also by using the new generation sensors the

vibration analysis becomes easier.

BIBLIOGRAPHY

1.

Vibration Studies at National Optical Institute,

Canada

2. www.mtiinstruments.com

3. www.fdb.no

4. www.intellisense.com

5. Institute of Engineers

1 comments:

Write commentsThe great information provided by you with the help of your blog.

ReplyThanks for the sharing a valuable blog that will teach how to know about Vibration Analysis and another like tools.

Vibration Analysis

EmoticonEmoticon